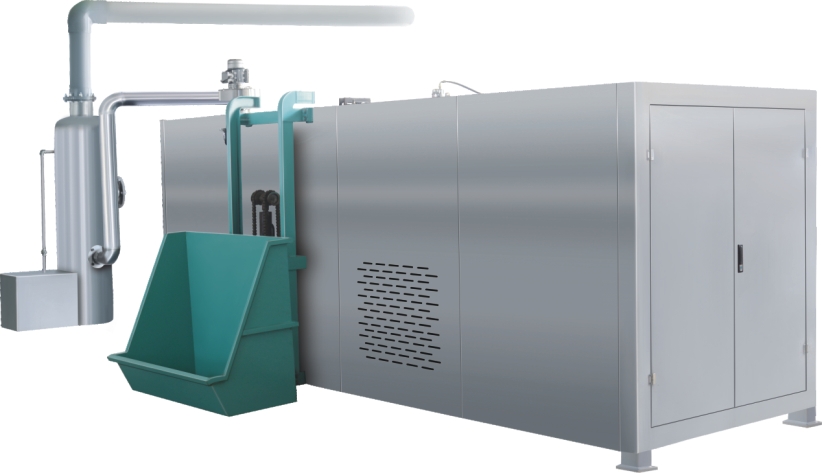

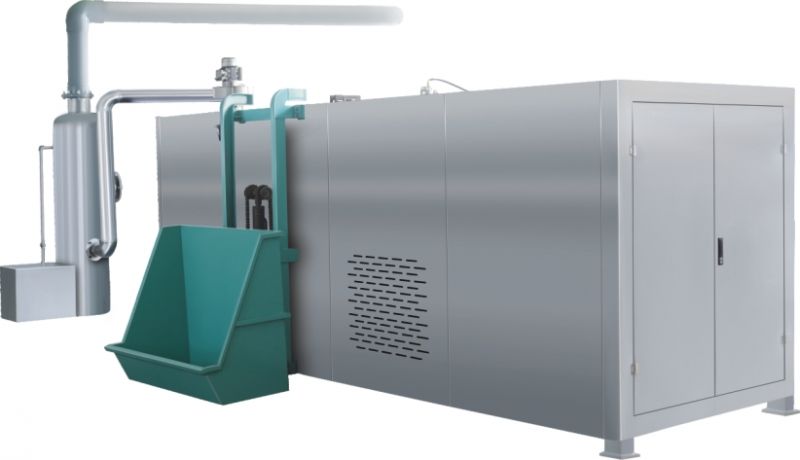

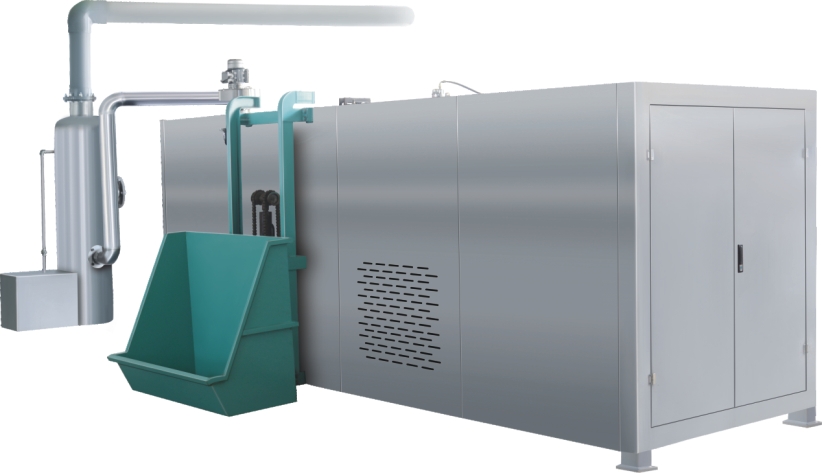

HIGH TEMPERATURE FERMENTATION MACHINE FOR DEAD ANIMALS

PRODUCT INTRODUCTION

The high-temperature fermentation machine for sick and dead animals is an environmental protection treatment equipment specifically designed for animal carcasses.Based on the environmental requirements of animal carcasses waste treatment,this equipment involves five steps:cutting,crushing,fermentation,sterilization,and drying of organic waste animals.After adding specialized microorganisms,the water vapor produced during the treatment process can naturally evaporate,be smokeless, odorless,and environmentally friendly,Successfully converting organic waste into harmless powdered organic raw materials, ultimately achieving batch environmental protection treatment and circular economy,achieving the effect of"reducing waste at the source and eliminating pathogenic bacteria".

PRODUCT FEATURES

1.Hydraulic lifting and feeding are automatically completed through the hydraulic lifting device,which is convenient and efficient, greatly reducing the labor intensity of the operator.

2.Exhaust gas treatment emissions:The exhaust gas generated during the treatment process is fitered by deodorization and disinfection devices and discharged without generating secondary pollution.

3.Energy saving design reduces power consumption by adopting a double-layer boiler with sandwich oil heat conduction

heating,and introducing variable frequency technology,greatly reducing power consumption and energy consumption during operation,energy 50%.

4.Intelligent control of various operations,LCD display of operating parameters and fault alarms.Remote control operation is convenient and simple,with fullautomation,avoiding the spread of diseases caused by human and animal contact.

5.The processing costs and benefits are basically the same or slightly surplus.Transforming waste into treasure,the product is high-quality and efficient organic feriizer,which is widely welcomed by the public and achieves resource recycling.

TECHNICAL PARAMETER

|

M o d e l

|

Processing capacity

(t/h)

|

Batch processing time

|

Effective volume

|

Installed power

( k w)

|

|

LTFJJ-2

|

2t/h

|

24h

|

4.5m³

|

58.07

|

|

LTFJJ-1.5

|

1.5t/h

|

24h

|

3.5m³

|

56.07

|

|

LTFJJ-1

|

1t/h

|

24h

|

2.5m³

|

42.57

|

Mobile website

Mobile website AliChat①

AliChat①